Manufacturing Facilities - Kirloskar Chillers

The future is manufactured, one component at a time.

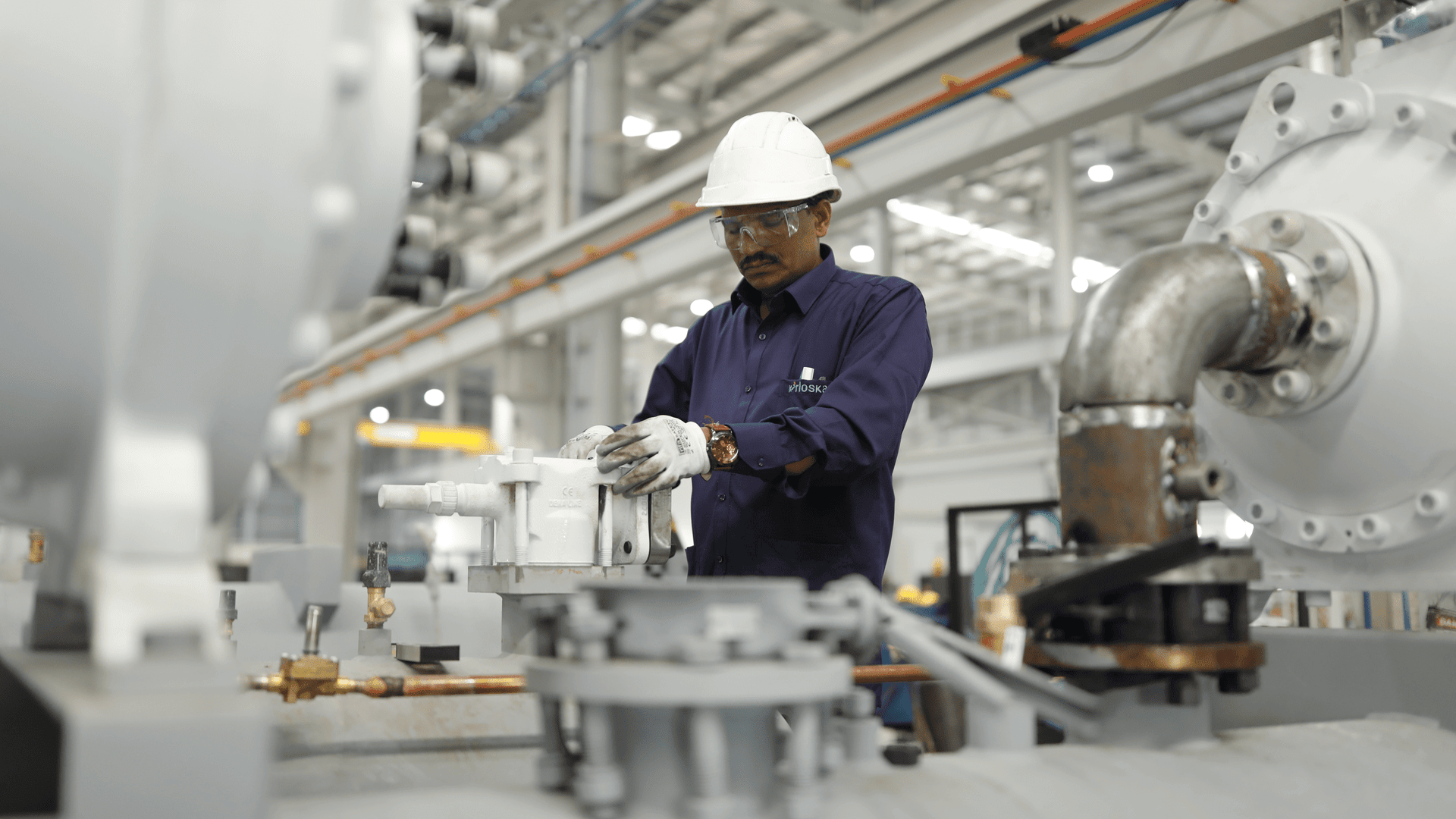

Since we revolutionized the Indian HVAC industry in 1996 by introducing a range of HFC chillers, we’ve always followed a customer-oriented, entrepreneurial approach to problem solving in the industry. This approach begins at the manufacturing stage with our state-of-the-art manufacturing and testing facility at Rajewadi, Shirwal, near Pune. Spread over 100,000 sq. ft., this facility is ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 certified. It is one of the only plants where both Centrifugal & Screw chillers are manufactured under the same roof.

The facilities include sections for centrifugal and screw compressor assembly and heat exchanger fabrication. The heat exchanger shop is equipped with machinery for tube sheet machining, tube expansion & pressure testing. The other sections of the plant cover various stages of the chiller manufacturing process, such as electrical & control panel assembly, chiller assembly, pressure testing, refrigerant charging, painting & insulation. Nothing we make is ever put out in the field without extensive testing. Our products are made to be reliable. What’s more, Kirloskar Chillers was the first chiller manufacturer in India to offer chillers certified under the AHRI 550/590 & 551/591 certification program. We were the first to establish an AHRI-certified test bed in India, which, even today, is one of the largest chiller test facilities in the country for both air-cooled and water cooled chillers.

Peering into the future requires Research & Development

Kirloskar Chillers prides itself on being a technology-driven company, responsive to the needs of its customers and alert to emerging global trends. As part of our belief in a future beyond boundaries, we focus on a relentless cycle of innovation that’s focused on creating more efficiencies within existing products and adding new features that create further value to the lives of those who experience our products. Our Engineering team uses advanced software tools for various aspects of chiller design. Vast experience in refrigeration system design, particularly in thermal & mechanical design as well as in-house expertise in Controller programming & logic development help us optimize chiller operations and enable us to remain a leader in chiller technology. We also believe in constant collaboration to help further the horizons of our expertise. We enlist experts for specialized engineering requirements like CFD analysis for impeller design, FEA for seismic studies, stress analysis and acoustic & vibration studies.