Turbotek - Kirloskar Chillers

The HFC 134a Refrigerant Advantage:

- Positive pressure design eliminating requirements of purge unit, annual oil maintenance, filter changes, etc.

- No issues of refrigerant availability

- No penalty on efficiency due to ingress of moisture or non condensables in the system

- High motor life

Simple Single Stage Design Advantage:

- Optimized impeller designs

- Very high efficiency

Unloading Advantage:

- Simple hydraulically operated inlet guide vane control

- Movable discharge diffuser, ensuring excellent stability at low load condition, minimizes likelihood of surging at low load conditions

- Unloads to 10% of full load

- Thermostatic / Electronic Expansion Valve provides superior refrigerant flow control over a range of operating conditions

- Better control of suction superheat

- Efficient operation at part loads compared to orifice plates / float devices

High Speed Gear Drive Advantage:

- Very compact design

- Lower vibration levels even at higher speeds

- Allows use of hydrodynamic bearings with infinite Life

- Selectable impeller speeds to match application & tip speed

- Easy to adapt to non-standard conditions

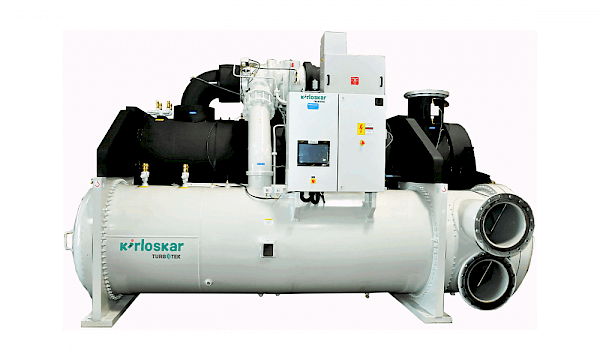

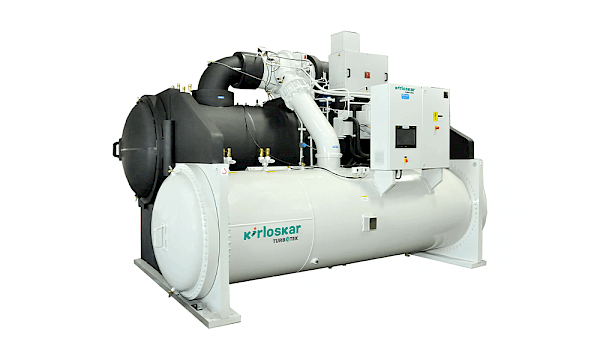

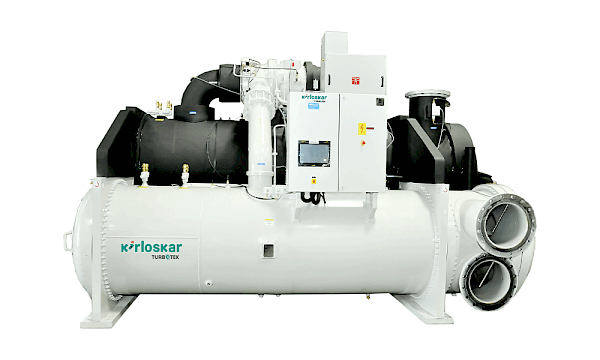

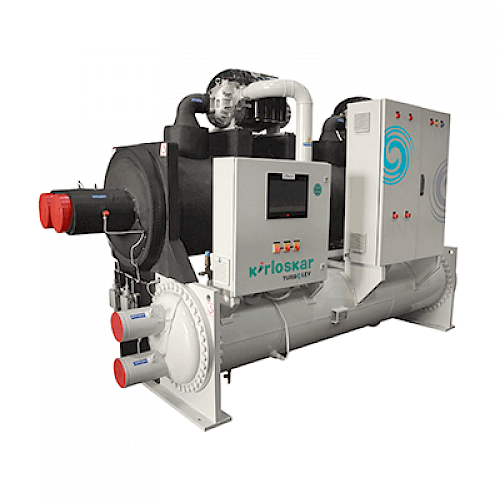

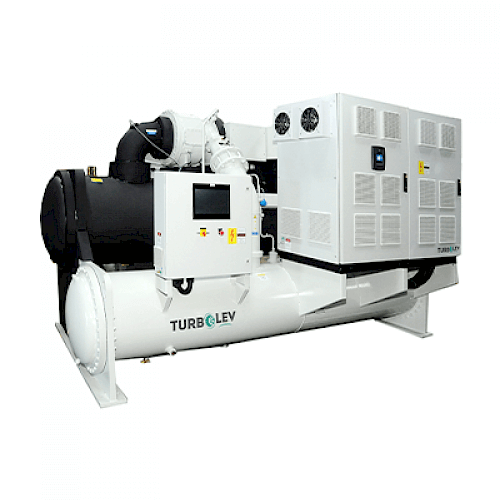

Kirloskar TURBOTEK® Centrifugal chillers offer unparalleled return on investment throughout their life cycle. Positive pressure design with ozone friendly HFC134a refrigerant ensures that all components operate above atmospheric pressure. This avoids air and moisture seepage into the refrigeration circuit and eliminates the need for a purge system, a drawback of chillers using negative pressure refrigerants.

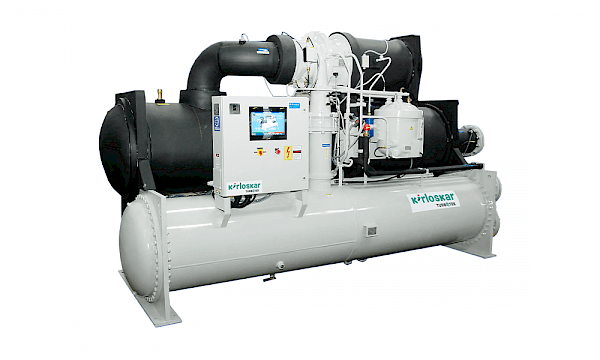

K-Smart, a microprocessor controller with user-friendly color touchscreen, graphical operating interface panel monitors and controls chiller performance. These chillers can also integrated seamlessly with user's Building Automation System (BAS) using BACnet, LonWorks or Modbus communication protocols.

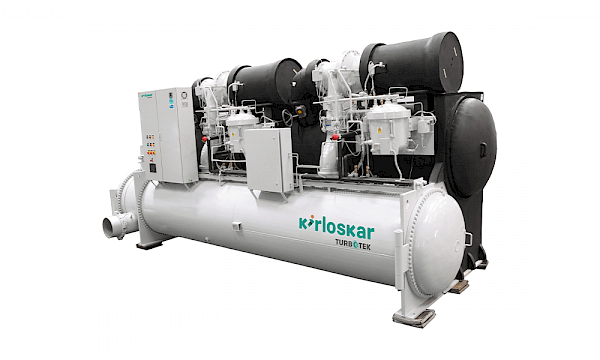

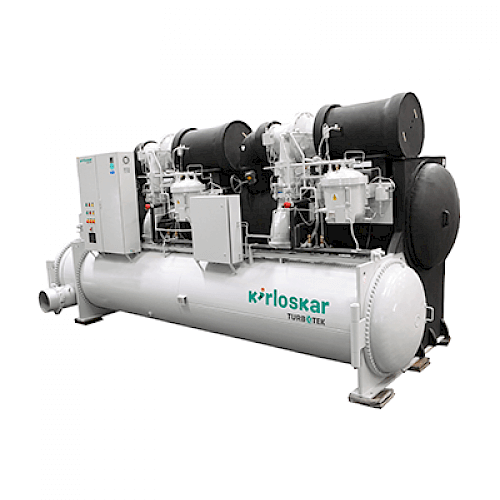

Smallest footprints help builders/architects/HVAC consultants save valuable floor space. Upgraded impeller designs result in substantial energy savings, with superior part load efficiencies. Variable frequency drives are available as an option. Chillers can be offered in single and dual compressor configurations.

| With Single Compressor | With Dual Compressor | ||

|---|---|---|---|

| Model No. | Nominal TR (kW) | Model No. | Nominal TR (kW) |

| KSC 063 | 200 ~ 320 (705 ~ 1125) | KDC 063 | 400 ~ 650 (1405 ~ 2285) |

| KSC 079 | 280 ~ 400 (985 ~ 1405) | KDC 079 | 560 ~ 800 (1970 ~ 2810) |

| KSC 087 | 400 ~ 650 (1405 ~ 2285) | KDC 087 | 800 ~ 1200 (2810 ~ 4220) |

| KSC 100 | 525 ~ 800 (1845 ~ 2810) | KDC 100 | 1100 ~ 1600 (3865 ~ 5625) |

| KSC 113 | 725 ~ 930 (2550 ~ 3270) | KDC 113 | 1600 ~ 1850 (5625 ~ 6505) |

| KSC 126 | 930 ~ 1200 (3270 ~ 4220) | KDC 126 | 1850 ~ 2400 (6505 ~ 8440) |

A Participating Company in the AHRI 550-590 Certification Programs

Kirloskar Chillers Private Limited way back in 2004, became FIRST chiller manufacturer in India to have its range of water cooled centrifugal and screw water chillers certified by AHRI under the AHRI 550/590 certification program. This authenticates Kirloskar Chillers' claim of chillers designed and manufactured to global standards. Kirloskar Chillers has a continuous commitment to supply chillers that perform as specified.

On-going performance verification of chiller capacity and power input provides the owner with specified performance in accordance with the AHRI Standard 550/590-2013. Further, In 2008, KCPL also became the first company in India to have it's chiller test bed certified by AHRI.